Plasma Arc Welding is the Matrix Edge

Plasma Arc Welding is the Matrix Edge

Matrix Drilling Products has taken a unique technology and applied it to manufacturing in-hole tools used in the mining industry.

At the heart of Matrix quality and superior in-hole performance of their drilling tools is a technology that is unique, differentiated and complex.

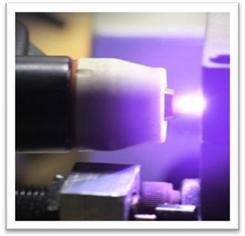

Plasma Arc welding (PAW) is a technology requiring simultaneous control or multiple variables which requires discipline and focus to realize its value – when mastered, it has extraordinary benefits.

The capital equipment cost for PAW is substantial versus other arc welding processes. As a result, it has been avoided because of the considerable investment required along with its complexity.

Plasma Arc technology is revered in certain industries such as Medical, Electronics, Aero Space and Aviation where superior weld strength is critical.

Statement from Aero Space manufacturer: GJ Langford – General Dynamic Corp:

Joint evaluation revealed excellent results. X-ray quality was defect-free (“water-clear”). Joint strength approximated 100% for mill-annealed material. Joint ductility was also high relative to parent material. This was established by Elongation and by Bend Radii determinations relative to parent material.

PAW is a high integrity process that fits the need for consistently delivering ultra strong welds such as the requirement in the construction of Drilling Tools.

Plasma Arc welding process is most effective when used in conjunction with automated equipment, and development of strict welding procedures such as operating windows for welding parameters.

It is an adept technology for welding components of different steel grades of varying thicknesses into a rigid structure – it’s weld penetration is superior.

Drilling Tools both Reverse Circulation Rod and Rotary Drill Pipe – require incredible strength to operate reliably, and continuously in the harsh onerous environments existent in drilling overburden formations and into bedrock which can be ultra hard, broken and abrasive. Couple this with requiring the application at thousands of feet beneath the earth’s surface. The RC Drilling Tools must endure a host of lateral stress, compressive stress, tension and torsional stresses along with shock loads transmitted by the Rock bit or Down Hole Hammer – these stresses are innate to the drilling process.

Unique Exceptional Strength

Plasma Arc Welds are precise and provide consistent and complete weld penetration which delivers their exceptional strength.

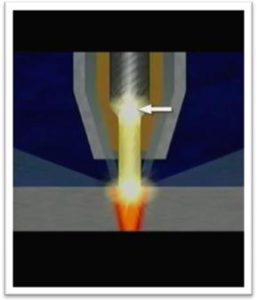

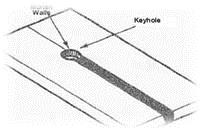

The Plasma Arc key hole mode produces full penetration welds integral effectively fusing of relatively thick materials in a single pass – To insure the quality of the welds, the presence of the keyhole is critical – In the keyhole mode, a penetrating hole is formed at the leading edge of the weld pool. The molten weld metal flows around the hole and solidifies behind the keyhole to form the weld bead. Therefore, keyhole welds are deliver complete penetration that is visually easy to confirm so both weld reliability and weld strength are key benefits of the Plasma Arc process.

The high depth to width ratio of the plasma arc weld – having more parallel sides is advantageous in minimizing angular distortion and is also characterized by a smaller heat effected zones than weld produced with other arc techniques.

The precision of the weld is key to the construction of the Reverse Circulation Drill Rod Assembly as welds must be completed in limited space and require complete, consistent, verifiable penetration.

Summary:

Plasma Arc Technology is unique – its ability to effectively fuse the RC Drill Rod components together incorporating incredible strength and durability in the completed assembly. Matrix Drilling Products have become expert in employing PAW to manufacture drilling tools of superior strength and durability. Matrix additionally utilize PAW effectively in the manufacture of Sonic, Rotary and Wire line Drilling Tools.