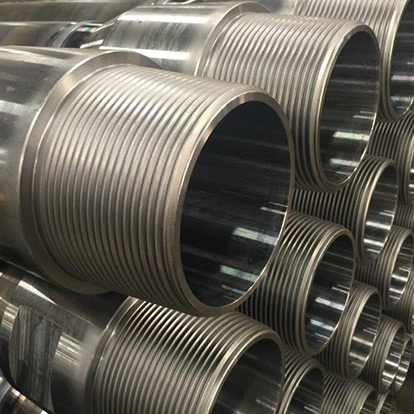

Sonic Drill Rod

Matrix sonic rods features robust plasma arc welded tool joint connections that have outlasted our competitors in head to head testing. Matrix uses multi-start threads for quicker make/break of tool joints.

Sonic Casing

Matrix sonic casing is built to last. Our tool joints are manufactured from high strength alloy steel. Our proprietary Matrix casing thread is a field proven connection. It’s a durable multi-start design for faster makeup and breakout. We offer a choice of midbody wall thicknesses and equip our casing with heavy duty tool joints which are fused to the midbody utilizing plasma arc welding technology. Our plasma arc welding process produces the industry’s strongest welds.

Core Barrels

Matrix offers a full range of sonic core barrels with dimensional choices to fit most scenarios you may encounter. Our core barrels are compatible with all Matrix drill rod and casing. Available sampling ID sizing from 3.375” to 8” See “Matrix Core Barrel Specification Table” for complete dimensional details.

Bolt-on Adaptors

Matrix offers versatility with our bolt-on adaptors designed to securely connect the flanged (spindle) adaptor to your choice of threaded connection. The bolt-on adapter provides quick change flexibility and as its name suggests is secured to the flanged spindle via a multi-bolt pattern. This provides complete adaptability to the full array of Matrix sonic drill rod and casing. As with all Matrix in-hole tools our bolt on adapters are manufactured with CNC precision.

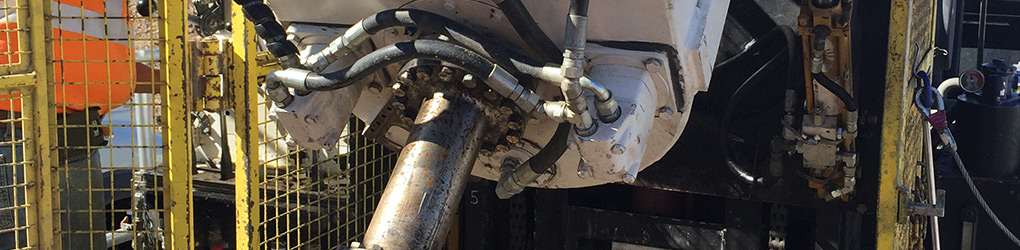

Flange (Spindle) Adaptors

Matrix manufacturers an assortment of sonic flange (spindle) adaptors. The purpose of these tools is to connect the sonic head (spindle) to the in-hole tools. Matrix flange (spindle) adaptors are designed to accept bolt-on adaptors to connect to our array of Matrix sonic drill rod and casing. We offer flange patterns that connect to leading sonic rig manufacturers and also custom manufacture to customer specification. Our CNC operators are experienced and highly skilled ensuring a quality product with a precision fit – which is very important as this component is responsible for the efficient transfer of sonic head energy to the drill string.

Extension Rods

Matrix sonic drill strings use an Extension Rod that is positioned between the Bolt on Adaptor and the Sonic Drill Rod. The Extension Rod takes the brunt of the making and breaking wear and tear, and is less expensive to replace vs a complete Drill Rod. The Extension Rod works as a “Saver Sub” in the drill string.

Hoisting Plugs

Matrix manufacturers Hoisting Plugs that are size specific and connect to each size of Sonic Drill Rod, Core Barrels, and Casing. Our hoisting plugs are very durable and equipped with a HD bail for reliable safe hoisting and lowering of our in hole tools

Fishing Tools

Matrix offers a range of fishing spear profile taps to match each size of our Sonic Drill Rod and Casing. The tap is machined with a matching box connections to the fishing string. We also custom manufacture spear taps to customer specification. Our taps are manufactured using case hardened 8620 alloy steel, and feature “V” threads to maximize their ability to tap into and hold lost tooling

Saver Subs

Matrix saver subs are manufactured from high strength alloy bar steel and are machined with exacting precision on our CNC lathes. The proprietary Matrix sonic thread profile was designed specifically to perform in a sonic drilling environment where vibrations cause standard thread forms to fail. The saver subs allow connection from the sonic extension rod to the various sizes of Matrix Sonic Drill Rod, Casing, and Core Barrels.