Capabilities

At Matrix we have the experience and infrastructure necessary to help with your most demanding projects. Manufacturing to a high-level for over 40 years, we take pride in delivering the highest quality products on time and to specification.

Engineering

Leveraging years of combined industry experience, our engineering team has the tools to help meet your most challenging requirements. Employing full-time engineers and draftsmen, we merge both extensive industry knowledge and the most current technology to meet your design needs. From advanced thread design to flow simulation and optimization, not only are we able to put ideas to paper, we can also simulate how they will respond in unique environments.

Product testing & Improvement

We embrace an atmosphere of continual improvement and we constantly strive to improve our already high-performing products. For example, we destructively test our proprietary thread forms to better understand their torque ratings and thresholds. We analyze wear patterns of drill rods returned from the field so we can design and incorporate improvements into future rods.

Although we haven’t yet found a way to make our products last forever, that doesn’t stop us from trying!

Quality Control

Our dedication to quality is relentless. From our ISO 9001:2015 Quality Management System to our comprehensive inspection programs, we ensure that every part that leaves a Matrix facility is given the utmost attention. Our commitment to quality doesn’t end there. We push ourselves to stay on top.

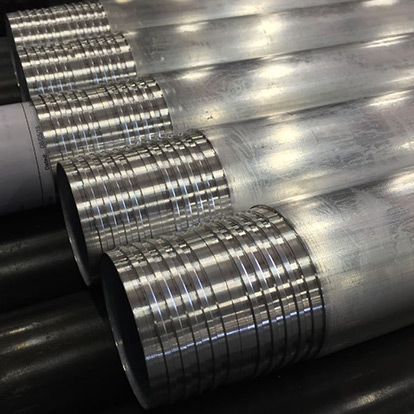

Raw Materials

We understand that the best parts must always begin with the best raw materials.

At Matrix, we only use the highest-quality steel sourced from American mills. We use mechanical tubes in the manufacture of our drill rod. We require our tubes to meet closely-held chemistry and mechanical property specifications.

Controlling Quality

A quality product starts with its design. We leverage our vast industry and fabrication experience to define and control those aspects of the part, which will be crucial to its performance. Each part is then manufactured by highly skilled machinists who use state-of-the-art CNC machines to hold design tolerances. Along the way, each part is meticulously inspected by numerous individuals to ensure that no part goes unchecked before leaving the Matrix facility.

Advanced Manufacturing

The ability to consistently produce to exact quality and precision does not happen by accident. Matrix utilizes some of the most advanced manufacturing techniques in the industry. Those techniques, coupled with our highly skilled and experienced workforce, allow us the flexibility to easily scale production to meet unique demands.

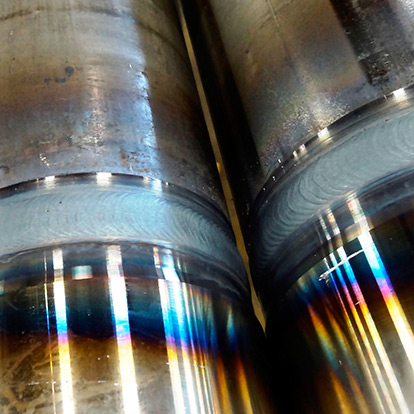

Welding

Matrix has perfected the process of Plasma Cold Wire Feed (PCWF) welding. This automated process minimizes the heat-affected zone, allowing for better mechanical properties. In short, PCWF welded drill rods are stronger and more durable than other arc or friction/inertia welded products.

Machining

The heart of machining at Matrix is the employee workforce. With many employees having worked at Matrix for more than 20 years, their knowledge and experience is invaluable to our production effort. Combined with over 20 advanced CNC machining centers, our workforce has the state-of-the-art tools necessary to produce at the highest level.

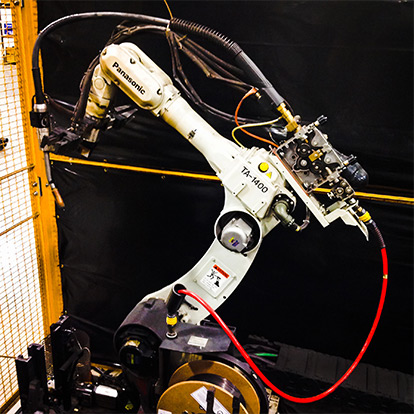

Automation

Matrix employs a number of automated systems on the production floor. Those automated processes, overseen by our experienced workforce, allow for parts to be produced at high volumes while still maintaining quality. From automated welding solutions to ‘lights-out’ machining centers, Matrix has the capacity to easily scale to meet high volume requirements.