“WJ” Series Drill Rod

Matrix manufactures AWJ, BWJ, and NWJ drill rod. This taper threaded rod is the workhorse of the Geotechnical and Environmental industries. The exceptional durability of the Matrix WJ rod can be attributed to the high strength alloy steel and the Matrix plasma arc welding process. The combination of the best materials and the industry’s strongest weld means unequaled reliability in the field.

“W” Series Drill Rod

Matrix offers AW – BW – NW – HW drill rod. The “W” thread has a square profile (not tapered, a DCDMA standard.) Typically used in the geotechnical drilling industry for shallow hole applications. The original “W” rod is a coupled product, however, Matrix can also manufacture it as a composite welded product.

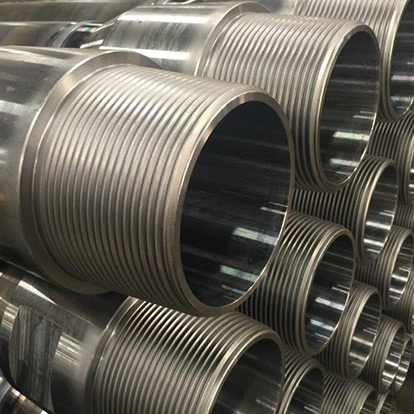

Standard Wireline Drill Rod

Matrix is an experienced manufacturer of wireline drill rod, celebrating over 40 years of operation. We offer several configurations of wireline rod. Matrix standard taper lock drill rod is available in NC, HC, and PHD sizes. This is a one piece parallel wall drill rod manufactured from 4130 Alloy Steel that is heat treated to maximize its strength and durability.

Non-Rotating Dual Tube Rods

This Non-Rotating RC Rod is used to together with an aerator sub for the purpose of cleaning out monitor wells. The rod and aerator sub direct compressed air to the ID of the monitor well, which creates the required air/water disturbance to effectively clean the monitor well. This is an effective technique and can be used at depth. The length of the RC string can be matched to the monitor wells screened interval to assure exact proximity. Matrix has manufactured this specialty rod in 1.750″ OD and other diameters are available on request.

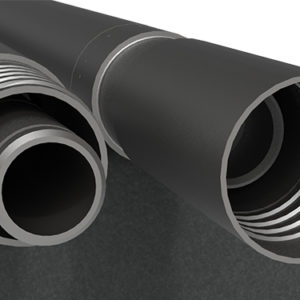

W, WT Casing

“W” series casing is a parallel wall one piece product with a square thread profile best suited for applications where the casing is advanced by driving it to depth. Popular in geotechnical drilling applications. Sizes: AW – BW – NW – HW – PW – SW – UW – ZW. Available in multiple steel grades.

“WT” series casing is almost identical to “W” series, however, it features a tapered thread making it easier and faster to makeup and breakout. Also, this product has greater torsional strength verses “W” casing and is recommended when the casing is being drilled into place. Common sizes: NWT – HWT – PWT. Available in multiple steel grades.

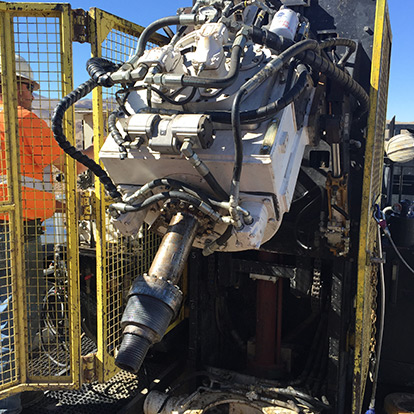

Nose Cone Push Points

Environmental Probe Rigs utilize nose cones to lead percussive soil, water, and air sampling tools down hole in search of contaminants. The sampling tools are driven by a percussive top hammer so the nose cones must be durable as they are driven and compress a pathway through the soils lithology advancing the bore hole. The nose cone is manufactured from hardened steel and is designed as an expendable item. Provide us with your dimensional specifications and Matrix will develop your quote for an exact nose cone required with a precision machined fit.