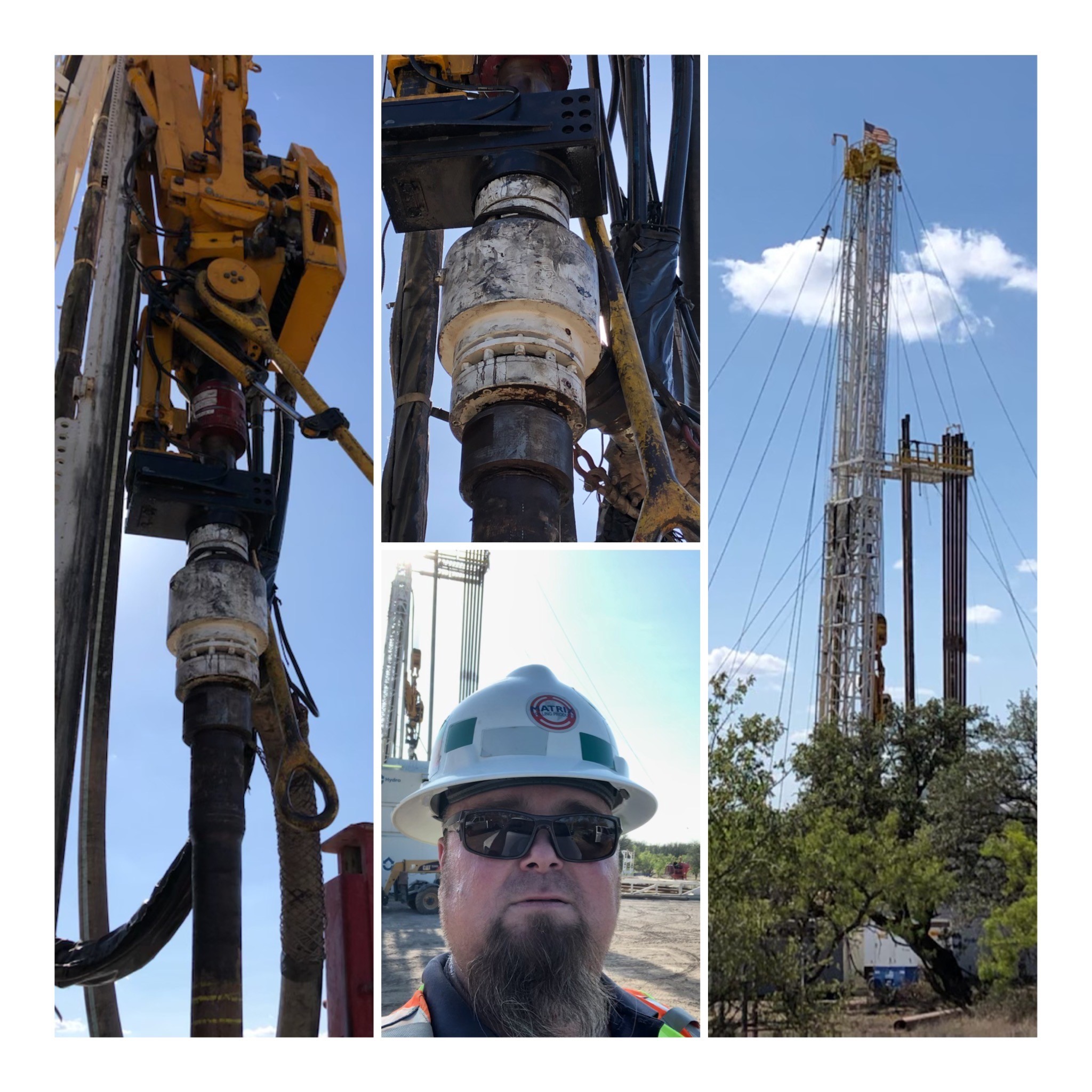

Drilling Deeper Water Wells in Texas with Matrix Side Discharge Swivel

Aaron Maurer, our field account representative for the Western US region recently visited our client Hydro at a drill site in Texas. Drilling is in our blood and is a highlight of the job to come out to the field and visit our clients. We take pride in merging our drilling experience with our engineering prowess to help put the right string in the right hands.

Hydro is using a Load Craft top drive rig, tooled with 6 5/8 drill rod with a Matrix 7″ swivel for flooded reverse circulation drilling and well development. Due to the extreme well depths, Hydro can safely and efficiently develop optimum water flow from the aquifer with the Matrix Swivel. Results show less time in development of the well due to minimal drill fluid ingress to the production zones. These are wells that will yield better water production for their client, and that is how we help our clients build bigger wells for bigger paydays.

Feel free to reach out if you have questions on your drilling operation and how Matrix Drilling Products can help you overcome your toughest in-field challenges.