Case Studies

Whether it is underwater mineral exploration or a ground water project several thousand feet into the earth, the Matrix fingerprint of quality can be found around the world. This is what relentless looks like:

DRILL SITES: Northern Canada – Ethiopia – Australia and the USA

CHALLENGE: To be able to utilize existing drill rigs with a smaller ID through the spindle with larger diameter RC Tools without being subject to limitations of the spindle diameter and a reduced flow volume of cuttings.

MATRIX SOLUTION: Developed a side discharge under-mount swivel that could be adapted to a variety of Drill Rigs within the Layne Drill Fleet that directed the cuttings flow below the spindle so the smaller diameter in the spindle was not a limitation to flow and drilling production.

WAYNE MELHORN'S COMMENT: “The Matrix team is very innovative and willing to try new things. They are flexible and incredible persistent when it comes to solving drilling challenges that would scare others off. Its that kind of spirit that has taken Matrix into different facets of the industry as a trusted reliable manufacturer.”

Layne Christensen Company

- Wayne Melhorn

Former General Manager, Supply Division

DRILL SITE: Northern Minnesota – Over Water Barge Drilling Project

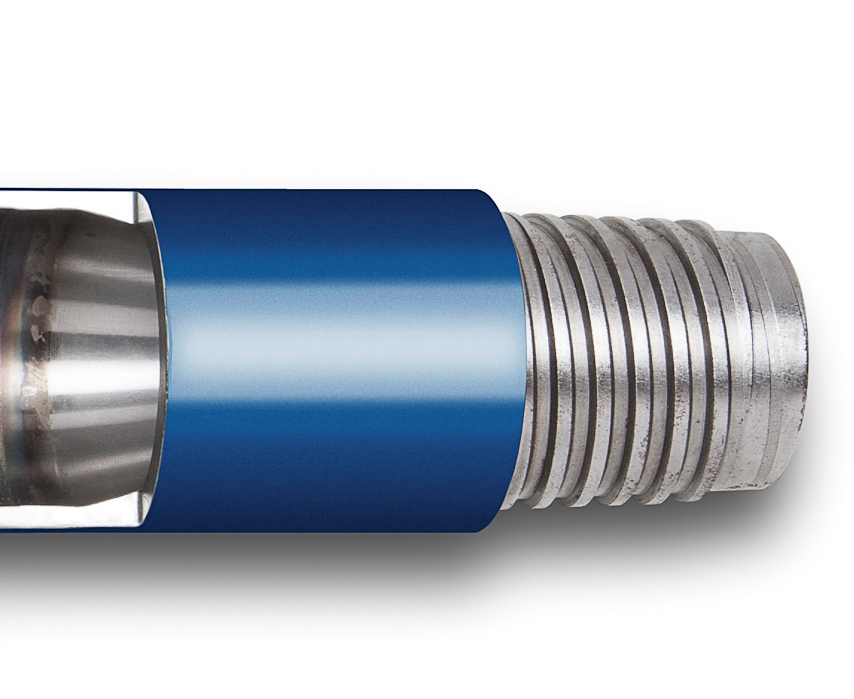

CHALLENGE: Develop a Wireline Drill String that was lighter in weight yet capable of yielding a “P” size core – required for bulk sampling purposes – The Wire Line Drill String Would have to drill to 3500 feet below the lake bed and the drilling would take place over water on a barge. The drill rod would also have to be able to endure wedging operations into the target zone below the 3500 ft. depth.

MATRIX SOLUTION: Matrix developed a 20 ft. Ultra Lite PHD/ (HWT) drill rod with a custom .156“ light-weight mid-body. The total rod weight achieved was 154 lbs. per 20 ft. length a 25% reduction over standard PHD drill rod. This unique Ultra light weight design was required to meet logistical limitations enabling easier movement of the tools to and from the remote barge site. It was also required to enhance tool handling on the barge. The overall goal was to realize higher operational performance in a limited, and restricted space environment. The quality and strength of the Matrix Drill Rod allowed the IDEA team to extract 50 tons of core sample in record time.

DICK BACKSTROM's COMMENT: “The team at Matrix doesn’t roll their eyes or make excuses when it comes to figuring out a custom drilling solution. They really latch onto this stuff and get excited about solving our problems! To have a supplier like that is huge.”

IDEA DRILLING

- Dick Backstrom

Founder & CEO

DRILL SITES: Global Contractor

CHALLENGE: Major Drilling specializes in a variety of drilling applications both surface and underground including wireline coring, reverse circulation, and geothermal drilling. Major Drilling also provides sonic drilling services and is active with Pre Collar drilling and fracking services for the Oil and Gas industry. While the need often arises for 20 ft. and 30 ft. pipe in the mining sector … for Major’s oil fracking a requirement arose for a 40 ft. drill pipe in the Bakken Trail. The Drill Pipe was 5 inch O.D. X 40 ft X 3 ½ IF – Connection.

MATRIX SOLUTION: While the 40 ft. requirement was an awkward request for other companies when Major Drilling put out its RFP, Matrix stepped up with a custom solution.

LARRY PISTO'S COMMENT: “Matrix has helped us diversify our services in the drilling field, it is safe to say the Matrix manufacturers the best quality Reverse Circulation pipe in the country. The Matrix team is knowledgeable and very ethical – dealing with them it's not about making a sale, their first priority is to solve your problem."

Major Drilling Group International

- Larry Pisto

VP, North American Operations

DRILL SITES: Alaska

CHALLENGE: Fly Job requirement for Ultra Light “N” Wire Line Drill Rod. Helicopter Maximum payloads are always a crucial factor on fly jobs and both rig and tools are kept to a minimum. This particular instance involved the client requesting that a specific bore hole that Major was in the process of drilling be deepened beyond its existing depth, which was also beyond the capacity of the drill rig on site utilizing standard wireline tools. To accommodate the customer’s request a lighter drill string was required to extend the depth capacity of the drill rig.

MATRIX SOLUTION: Matrix designed a custom drill rod it’s “Aluminum/Steel composite N” wireline drill rod. The drill rod utilized an aluminum mid body with a steel tool joint. Weight of the Drill Rod per 20 ft. length was 42.1 lbs. The Ultra Light drill rod allowed Major Drilling to meet its client’s request and to complete their project efficiently.

LARRY PISTO'S COMMENT: "We know when Kent says he can deliver a product – he can - he’s not just talking. These guys work wonders."

Major Drilling Group International

- Larry Pisto

VP, North American Operations

DRILL SITES: Canada – Africa – Australia – and the USA

CHALLENGE: SIMCO needed a light weight, easy to use, yet durable drill rod to complete its equipment offering to the Geothermal drilling industry. Speed and ease of make up/breakout was also an important feature to address the Geothermal Industry, where a premium is placed on production.

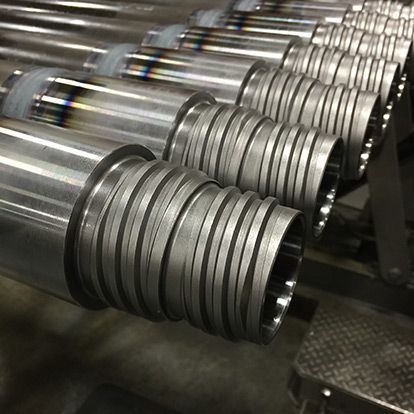

MATRIX SOLUTION: Matrix designed and built a lighter, high flow, faster make up / break out PDQ Drill Rod. The Drill Rod’s unique two start thread enabled easier and faster make-up. The use of alloy steel allowed reduced Mid Body wall and its weight from 100 lbs .to 65 lbs. while retaining the rod’s overall strength. The ID of the Drill Rod was also maximized allowing for a significant increase in water flow. This drill rod is now the “ SIMCO PDQ Drill Rod” and a permanent part of a SIMCO Rig package.

RICHARD CLARK'S COMMENT: “We’ve tested the PDQ Rod under tremendous stress in the most rugged terrains, and it held up time after time. The Magic is in the Matrix welding process, no one does it better. This rod was a real game changer for us – Matrix is a company that measures its success on the success of its customers."

SIMCO DRILLING EQUIPMENT

- RICHARD CLARKE

Director of Sales and Marketing

DRILL SITES: Canada – Africa – Australia – USA

CHALLENGE: Provide a better Rotary Drill Pipe compatible with VERSA -DRILL Rigs for Water Well and Geothermal Markets – Drill Pipe that is capable of working in remote areas of the world with the US Army’s Water Well Drilling Program such as Afghanistan.

MATRIX SOLUTION: Matrix utilizing it’s Plasma Arc Welding technology provides a Rotary Drill Pipe that combines the use of an alloy steel light weight Mid Body together with a strong durable Tool Joints. This is a manufacturing combination that is unique to Plasma Arc welding ---- its ability to efficiently reliably fuse a ultra light wall MB to a heavier wall tool joint provides the driller with exceptional wear life, easier transport, and onsite handling in remote locations.

MARCUS LAIBE'S COMMENT: "Laibe / Versa-Drill customers buy our drill rigs for the quality and reliability so it was important for us to find a tooling manufacturer that followed that same standard and why we choose to offer Matrix products."

Laibe Corporation / VerSA-DRILL

- marcus laibe

President

DRILL SITES: In New Zealand near Christchurch, New Zealand

CHALLENGE: Pro Drill were faced with a 150,000 meter Geotechnical program following the Christchurch Earthquake. The formation was glacial sands, gravel, and silts and extremely abrasive. Prior to Pro Drill’s introduction of Sonic Drilling to the project, an H string of wireline coring tools would wear out in a single month of drilling.

MATRIX SOLUTION: Matrix designed a line of sonic drilling tools using highly durable alloy steel and our Matrix Sonic double start thread. We were able to provide Drill Pro with their sonic tools including the Matrix Sonic 5” Casing.

RUSSELL SHERWIN'S COMMENT: “I never knew the importance of quality casing, we used the Matrix casing throughout the course of the project, and never lost or broke a length. We have heard horror stories on other systems that were used – without a doubt quality pays.”

PRO-Drill

- RUSSELL SHERWIN

Managing Director

DRILL SITES: Primarily in Nevada and western states. Art initially worked for Eklund Drilling Co. which was acquired by Boart Longyear Company in 2008. Art’s career with Eklund and Boart Longyear was primarily spent in the mineral exploration business primarily in the western U.S. with the majority of the drilling being in Nevada.

CHALLENGE: Nevada is known for it’s unfriendly hard, broken, abrasive formations. Art required a drill string that would deliver consistent performance and longevity in these rugged conditions.

MATRIX SOLUTION: The development of an ultra strong efficient design that minimized vibration was key, and was enabled by our design team, and use of Plasma Arc welding technology.

ART STEELMAN'S COMMENT: "We recently retired a Matrix RC Drill Rod string 5.5” x 3” x 20 ft. that was used for a full 8 years of continuous duty, a good example of normal Matrix RC Rod wear life. This string drilled 24 hours a day -10 days on 4 days off which is a standard shift schedule for mineral drilling in Nevada. This 24 hour a day use went on for over 8 years all on the same Schramm 45 EX drill rig. The string received regular maintenance – changing o’rings and rod string rotation."

Art further advised the RC string had a single inner-tube replacement after 5 years on approximately 60% of the pipe and the balance of 40 % of the RC Drill Rod still using the original inner-tubes. The cost to rebuild was approximately 30 Percent of the original Drill Pipe – the inner tube replacement was accomplished by Matrix.

Art stated that Matrix’s responsiveness was very good - citing a couple of examples, one being the customizing of their 4.5 inch RC drill string to increase air flow, and thus enhance depth capacity for an Alaskan deep drilling program with holes 2,000 to 4,000 ft in depth. The design modification significantly increased our productivity and turned a job that had been a loser in to a success.

BOART LONGYEAR

- ART STEELMAN

Operations Manager

DRILL SITES: USA

CHALLENGE: To complete deeper wells.

MATRIX SOLUTION: Substitute current tooling with Matrix 3.5” Max Flow Lite Pipe. The reduced weight allows the rig to drill deeper, while the larger watercourse provides a more efficient path for drilling fluids.

MONTE RICHARDSON’S COMMENT: “In our general area we began to witness the need for deeper well completions. The Matrix design fit the bill for incorporation into the construction of these wells. By adding capability to our existing equipment, in multiple instances, we have witnessed a fuel burn rate reduction of over 35% as compared to previously used strings and bottom hole assembly designs.

“We plan on continuing to configure our equipment with Matrix drill pipe. Thank you for making a great product.”

J & S Water wells

- monte richardson

President