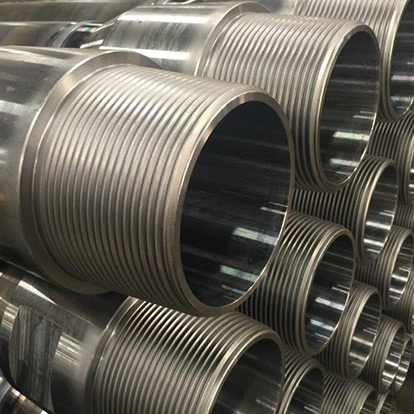

Standard Wireline Core Rod

Matrix is an experienced manufacturer of wire line drill rod. Celebrating over 40 years of operation, we offer several configurations of wire line rod. Matrix standard taper lock drill rod is available in NC, HC, and PHD sizes. This is a one piece parallel wall drill rod manufactured from 4130 alloy steel. The tool joints have been heat treated to maximize its strength and durability.

Composite Lightweight Wireline Drill Rod

This plasma arc welded product features internally upset tool joints with a lighter wall mid body than our standard one piece wire line drill rod. This lighter mid body provides a substantial weight advantage: over 35% reduction in weight on 10 ft. HCC rod verses HCC one piece drill rod. Size range NCC – HCC – PHD composite.

Deep Hole CHD Wireline Core Rod

CHD wireline drill rod was originally developed to address a requirement for a dependable drill string for deep hole gold exploration in the South African mining industry. As its reputation grew as a reliable deep hole coring drill rod it was used extensively in the slim hole oil and gas industry with applications worldwide by companies such as Standard Oil, Texaco, and Total S.A. The North American geothermal industry also found the CHD drill string an excellent match for their deep coring applications.

From a design standpoint the Matrix CHD drill rod is an internally upset product with a robust tool joint fused to a lighter wall midbody using plasma arc welding technology.

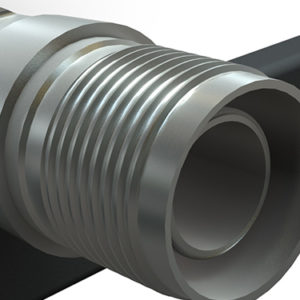

Matrix CHD Drill Rods feature a double buttress thread which is unique in that it can deliver both exceptional strength for depth and the durability perform on larger drill rigs used in deep hole coring operations. CHD strings are commonly known as CHD 76 – CHD 101 – CHD 134 for their respective hole diameters. The CHD drill rod is available in diameters 69.9 mm – 94mm – 127 mm in lengths up to 6 meters.

Pre-Collar Casing

Primarily used in diamond coring applications. On large coring projects with heavy overburden a rotary drill is used to pre-collar the borehole to bedrock, as a rotary drill is much more adept and efficient in drilling the overburden geology verses a diamond core drill. Once bedrock is reached by the rotary drill, it stops drilling and cases the bore hole with pre-collar casing. A diamond coring rig is then brought in to core the borehole to its termination point while working inside the pre-collar casing. The pre-collar casing typically uses a “WT” taper thread profile and often times a lesser grade of steel due to the fact that many times it is set to a shallow depth and dedicated to the bore hole. Matrix offers a choice of steel grades to match the project application (shallow or deep.) Available sizes: NWT – HWT – PWT. Lengths: 10’, 20’, and 30 ft. or as required.

Ultralight AI & Ti Wireline Drill Rod

Matrix’s aluminum drill rods are manufactured from high-tensile aluminum tubing that weighs 50% less than comparable steel. Titanium is the perfect solution for demanding drilling projects due to its high strength-to-weight ratio, flexibility, reliability, corrosion resistance, and longer fatigue life.

Non-Magnetic Drill Rod

Matrix offers a non-magnetic wireline product line machined from 304L stainless steel. This product is typically used with sensitive surveying equipment.

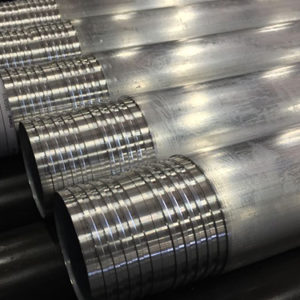

W, WT Casing

“W” series casing is a parallel wall one piece product with a square thread profile best suited for applications where the casing is advanced by driving it to depth. Popular in geotechnical drilling applications. Sizes: AW – BW – NW – HW – PW – SW – UW – ZW. Available in multiple steel grades.

“WT” series casing is almost identical to “W” series, however, it features a tapered thread making it easier and faster to makeup and breakout. Also, this product has greater torsional strength verses “W” casing and is recommended when the casing is being drilled into place. The casing choice in the mining industry. Common sizes are NWT – HWT – PWT. Available in multiple steel grades.

Subs and Accessories

Fishing Tools

Matrix manufactures recovery taps for wire line drill rod and casing. Matrix taps are a spear end profile with self-tapping “V” threads that are case hardened for maximum cutting and gripping action. Available in sizes for most wireline strings or to customer specification. Taps are machined as standard with the appropriate box end connection to connect to the fishing string.

Subs

Matrix manufacturers a wide array of subs to complete your wireline drill string. We offer thread profiles compatible with most wireline drill rod and casing, including adaptors for connecting to water swivels and hoisting plugs. We manufacture our subs from heat treated alloy steel, and you can count on a precision thread profile from our CNC machining centers.