Part 3 of 3 – Intro to Drilling with DT Reverse Air and Flooded Reverse Methods

Dual Tube Flooded Reverse Circulation Drilling

Dual tube methods have become standard practice in mining, water well, and large borehole drilling in recent years. With the growing popularity of these methods it is hard to believe that basic information on how these methods work can be difficult to come by. This blog series is meant to simply explain the concepts behind some of the most common applications of Matrix’s dual tube product line as used by our customers. As you are reading, keep in mind that we are NOT drillers. We are a custom manufacturing facility who specializes in producing dual tube for the drilling industry. If you have questions or would like to know more please contact us.

In this part of the intro to drilling series we will be looking at the method of dual tube flooded reverse circulation drilling using a drag/wing bit. If you haven’t already, check out Part 1 of our “Introduction to Drilling with Matrix Dual Tube” series Reverse Circulation Drilling with Air using a Rock Bit (Tri-cone/PDC), and part 2: Conventional DTH Hammers and DTH RC Hammers. If you would like to read more about any of the Matrix components discussed in this article check out our products page.

Dual Tube Flooded Reverse Circulation Drilling

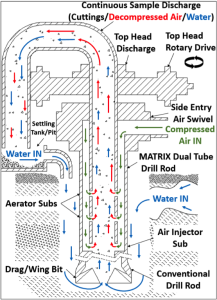

Flooded reverse Circulation drilling with dual tube is a totally different concept and geared toward a totally different market. This method has been embraced by the water well industry as it can produce a very good large diameter well. After the side entry air swivel energizes the annular area (as shown in figure 1,) the air is directly injected into the flooded inner tube before reaching the bit with the use of an air injector sub. The air decompresses and expands inside the flooded inner tube lowering the density of the inner column of water. The denser outer fluid column forces the inner column up to the surface at increasing velocities creating “nature’s mud pump” sucking the fluid and cuttings from the bottom of the flooded borehole. Subsequent aerator subs are built into the string to control the air pressure required to overcome the static water column pressure in the borehole. The cuttings discharge through the top head drive spindle where they are then directed into a settling pit or tank with the water returning to the borehole for a closed loop. Tri-cone or PDC bits can be used in place of the drag/wing bit. Conventional drill rod can also be used between the bit and air injector. This method requires that the hole stays fully flooded. Water falling into the borehole will cause washout; meaning loss of expensive tooling.

Figure 1: Sample Flow. Dual Tube Flooded Reverse Circulation Drilling with Drag/Wing Bit

Waiver: The views expressed in this article are the author’s opinions and are based on engineering education, skills, and experience gained in working with many different customers in the industry. No part of this article is intended to replace or supersede any information supplied by others. The contents of this article may not be used for any type of legal action.