Part 1 of 3 – Intro to Drilling with DT Reverse Air and Flooded Reverse Methods

Reverse Circulation Drilling with Air using a Rock Bit (Tri-cone/PDC)

Dual tube methods have become standard practice in mining, water well, and large borehole drilling in recent years. With the growing popularity of these methods it is hard to believe that basic information on how these methods work can be difficult to come by. This blog series is meant to simply explain the concepts behind some of the most common applications of Matrix’s dual tube product line as used by our customers. As you are reading, keep in mind that we are NOT drillers. We are a custom manufacturing facility who specializes in producing dual tube for the drilling industry. If you have questions or would like to know more please contact us.

All dual tube projects use the concept of reverse circulation drilling. This means that the cuttings come up the inside of the pipe rather than up the annular space in the borehole. One important thing to note here is that reverse circulation (RC) drilling can also be accomplished with conventional drill rods in a number of different ways, but these methods should not be confused with the dual tube RC methods we will be discussing here. Dual tube is being used in two manners, primarily, reverse circulation with air and flooded reverse circulation. Let’s take an in-depth look at these methods and the products Matrix custom manufactures to turn these concepts into reality.

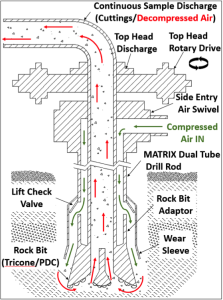

The first method we will look at is reverse circulation drilling with air using a rock bit (Tri-cone/PDC) (shown in figure 1.) This method uses a side entry air swivel below the top head drive to insert compressed air into the annular area between the ID of the outer tube and the OD of the inner tube. The air then moves down the string and through a rock bit adaptor assembly located directly above the bit. This assembly contains a wear sleeve that releases the compressed air into the borehole near the face of the bit. The air decompresses (violently) and the pressure drop sweeps the cuttings across the bit face and up through the center of the API pin up connection of the tri-cone and into the inner tube. A lift check valve prevents the back flow of air and cuttings into the pipe annulus which could otherwise block this passage. The cuttings travel up the inner tube at a high velocity and out through the top head discharge hose. In mineral exploration, these cuttings are then directed to a collection system which separates the geological material so that samples may be collected and logged. This continuous real-time sampling method allows the driller to know exactly what depth and what formation he is drilling within a matter of minutes.

Figure 1: Sample Flow. Dual Tube Reverse Circulation Drilling with Air using a Rock Bit (Tri-cone/PDC)

Interested in reading more? Check out the next two installments in our “Introduction to Drilling with Matrix Dual Tube” series! Part 2: Conventional DTH Hammers and DTH RC Hammers and Part 3: Dual Tube Flooded Reverse Circulation Drilling.

Waiver: The views expressed in this article are the author’s opinions and are based on engineering education, skills, and experience gained in working with many different customers in the industry. No part of this article is intended to replace or supersede any information supplied by others. The contents of this article may not be used for any type of legal action.