About

Made in the U.S.A., Matrix drill rods and in-hole tools continue to prove reliable and economical worldwide. Our dual tube is used to explore for and quantify mineral reserves, as well as produce water wells and dewatering holes.

With two locations, Tennessee and Idaho, Matrix is central to drilling operations nationwide. Forty years of innovative engineering has proven that all in-hole tools are not created equal. But don’t just listen to us. Listen to the people who count on our tools - day in and day out.

This is what relentless looks like.

Our Mission: To help our drilling partners be successful.

Matrix has been a pioneer in the drilling industry. We are quick to roll up our sleeves and jump in the trenches to better understand the challenges you face in the field.

How do we do it?

We start with the best alloy tubes available from U.S. mills. Our skilled production team combines the field experience of our clients and our experienced staff with state-of-the-art computer controlled equipment to manufacture the best drilling products available. These innovations have produced dual tube without connector tubes, rock bit adaptors with simple reliable valves, wire line core systems for depths to 20,000 feet, durable sonic tooling and much more.

40 years of game-changing innovation and quality.

And we’re just getting started.

The drilling industry is defined by the reality of unexpected challenges. We respond to that reality. While others may shrink back at your custom engineering requests, Matrix steps forward.

The ability to find an engineering and design solution consistently, is our norm. We turn the possible into reality for our customers. Providing the exceptional is what successful drilling operations have come to expect from Matrix.

We didn’t get here overnight. Family-owned for two generations, a passion for service and a steady allegiance to quality is in the Matrix DNA. Partnering with our clients to solve problems in the field has shaped everything about how Matrix does business.

Bob Peters founded Matrix Drilling Products in 1976. A career engineer, known in drilling circles worldwide, Bob has partnered to engineer technologies that have changed the drilling industry. In 2004, Bob put his legacy of innovation and quality into the hands of his son, Kent Peters, who has been serving Matrix clients with the same tenacity and passion as his father.

Kent expanded product lines, increased efficiencies and added machinery that allowed Matrix growth and a seat as a premier Dual Tube Reverse Circulation manufacturer. In October 2018, Kent completed the Matrix business continuation plan by adding Chris Delahunty.

Chris, a long-time Matrix client, comes from a technical drilling and engineering background of over 20 years, in exploration, geothermal, water, construction and science. By continuing the family dynamic of ownership, Matrix will remain independent and valuable to all in the drilling industry.

Our innovation, excellent products, client support, and improved process quality, will ensure the availability, reliability and longevity of Matrix to our clients, vendors, and employees.

You can count on us!

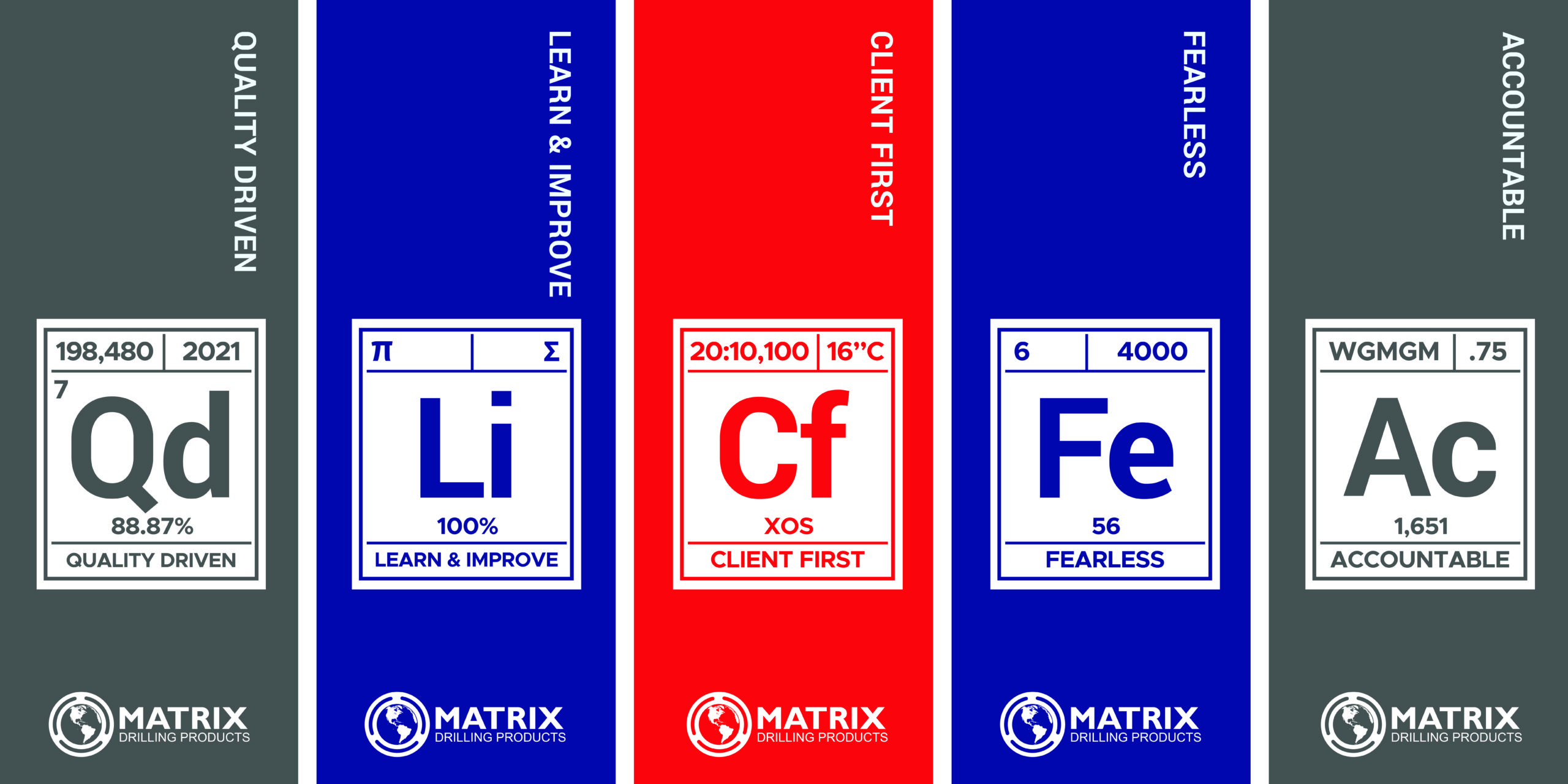

Our Culture: Integrity, honesty, innovation, quality

Many Matrix employees have been with us for 20+ years. They know the specs and stories behind the evolution of each Matrix product and the customers who use them. We are proud to have these team members pouring their talent, skill and pride into every Matrix product everyday.

Meet the Matrix Team

Loyalty translates to quality.

Our Facilities: State-of-the-Art

Matrix’s state-of-the art facilities and proprietary threading and welding process continue to build tools that give our customers a true production edge over their competitors in the field. Our top-of-the-line manufacturing equipment allows us to turn requests around by scaling our process and capacity as needed.